Some jobs are so dangerous and some men are so impervious to fear that somehow they make a perfect match and accomplish the impossible. I can think of miners, going down into the ground. Firefighters, who daily go into burning buildings. Steelworkers, those guys who walk on steel girders high above the streets. I wouldn’t, no check that, I couldn’t do any of those jobs. There are a few other jobs I am thinking of to add to that list, which would be bridge builders, dam builders and tunnel builders.

Some jobs are so dangerous and some men are so impervious to fear that somehow they make a perfect match and accomplish the impossible. I can think of miners, going down into the ground. Firefighters, who daily go into burning buildings. Steelworkers, those guys who walk on steel girders high above the streets. I wouldn’t, no check that, I couldn’t do any of those jobs. There are a few other jobs I am thinking of to add to that list, which would be bridge builders, dam builders and tunnel builders.This brings to mind Mike Rowe, who hosts the interesting show on Discovery network called Dirty Jobs. He also does jobs that make you very dirty, but none of which endangers his life each episode. Mike is a man that has moxie, he seems eager to try anything, but I digress.

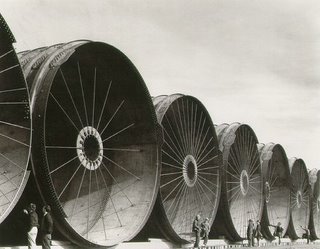

I got to thinking about all this when I discovered the above picture taken by Margaret Bourke-White called Diversion Tunnels. Being the curious type I wondered what that was. Bourke-Whites picture was taken at the Fort Peck Montana project, but the following I found about the construction of the Hoover Dam is much more descriptive of the danger involved.

Diverting The Colorado River Around Hoover Dam Construction

Before actual Hoover Dam construction could begin, the Colorado River had to be temporarily diverted around the dam construction site. It was a daunting, difficult project. At that time there were no roads into Black Canyon, so initially, dam workers and equipment had to be brought by boat. Over time, roads were built and catwalks were stretched across the river. Summer temperatures often reached 140 degrees in the canyon and the winter months brought freezing.

Carving the diversion tunnels was a slow, tedious process that exposed dam workers to immense danger from blasting, falling rocks and diesel gas fumes spewed by the trucks that carried out blasting debris. Compressed air was circulated into the tunnels through large pipes. However, despite the difficulties, through intramural competition of the crew shifts, the tunnels would be completed almost a year early.

But in the beginning, it took countless men to make even an inch penetration into the canyon walls. To quicken the process, a drilling “Jumbo Truck” was retrofitted with layers of platforms that were backed into the face of canyon walls. This enabled 20-30 men to simultaneously drill holes for blasting powder. Eight of these jumbo trucks were implemented and lights were installed permitting around the clock progression.

The blasting holes were filled with dynamite with a ton of dynamite used for about every 14 feet of tunnel. After explosion, dump trucks hauled the rock debris downriver and placed in spoil dumps along the canyon for later use.

The diversion tunnels were lined with intricate forms for concrete lining. Initially a base of concrete was poured. The sidewalls were then poured into moveable sections of steel form and rail directed cranes were used to place the concrete. Pneumatic concrete guns were used to fill the overhead forms resulting in a total concrete lining that was 3 feet thick.

Previously, a barrier across the inlets to the Arizona side tunnels was installed. When the Arizona tunnels were ready to accept water flow, the barrier was breached with explosives and the flow began through those tunnels. Earthen and rock debris were trucked in and dumped from a trestle to block the Colorado River channel which forced the flow of water into the diversion tunnels. Eventually, cofferdams were built at the entrance to the other tunnels so they all worked as a team to divert water around the Hoover Dam construction site.

The core heart of Hoover Dam construction was now ready to begin.

I take my hat off to all these brave men.

3 comments:

Post a Comment